What is hard disk drive?

A hard disk drive (often shortened as hard disk, hard drive, or HDD) is a non-volatile storage device that stores digitally encoded data on rapidly rotating rigid (i.e. hard) platters with magnetic surfaces. Strictly speaking, “drive” refers to the motorized mechanical aspect that is distinct from its medium, such as a tape drive and its tape, or a floppy disk drive and its floppy disk. Early HDDs had removable media; however, an HDD today is typically a sealed unit (except for a filtered vent hole to equalize air pressure) with fixed media.

How hard drive works?

A hard disk is a sealed unit containing a number of platters in a stack. Hard disks may be mounted in a horizontal or a vertical position. In this description, the hard drive is mounted horizontally.

Electromagnetic read/write heads are positioned above and below each platter. As the platters spin, the drive heads move in toward the center surface and out toward the edge. In this way, the drive heads can reach the entire surface of each platter.

Hard drive physical components

PLATTERS:

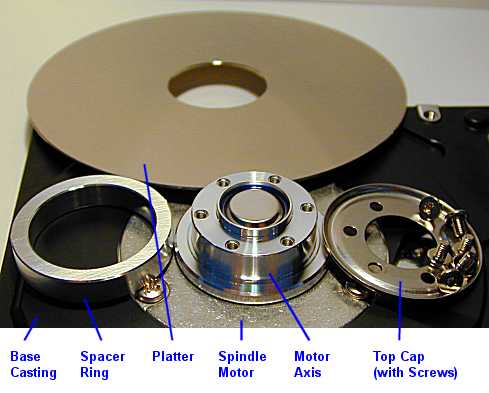

Platter is a circular, metal disk that is mounted inside a hard disk drive. Several platters are mounted on a fixed spindle motor to create more data storage surfaces in a smaller area. The platter has a core made up of aluminium or glass substrate, covered with a thin layer of Ferric oxide or cobalt alloy. On both sides of the substrate material, a thin coating is deposited by a special manufacturing technique. This, thin coating where actual data is stored is the media layer.

When the magnetic media is applied to the surface of the substrate material, a thin lubricating layer is applied to protect the material. This complex three layered media is discussed in detail as follows:

THE SUBSTRATE MATERIAL:

The bulk material of which platters are made up, forms the base on which media layer is deposited. The substrate has no specific function but to support the media layer. The most commonly used material for making this physical layer is an Aluminium alloy. This alloy is rigid, lightweight, stable, inexpensive, easy to work with and is readily available. Earlier, since the gap between the heads and the platter was relatively high, the platter surface being smooth and flat was less of an issue. However, as technology advances, the gap between heads and platters is decreasing and the speed that the platters spin at is increasing. For this reason demand for alternatives on the platter material are increasing. Glass platters are replacing aluminium platters because they provide improved rigidity, better quality, thinner platters, and thermal stability.

MEDIA LAYER:

The substrate material forms the base upon which actual recording media is deposited. The media layer is a thin coating of magnetic material applied to the surface of the platters and where the actual data is stored. Its thickness is only a few millionths of an inch.

Special techniques are employed for the deposition of magnetic material on the substrate material. A thin coating is deposited on both sides of the substrate, mostly by vacuum deposition process called magnetron sputtering. Another such method is electroplating, using a process similar to that used in electroplating jewelry.

PROTECTIVE LAYER:

On the top of the magnetic media, is applied a super-thin, protective, lubricating layer. This layer is called the protective layer because it protects the disk from damage caused by accidental contact from the heads, “head crash” or other foreign material from entering the drive

PLATTER DIVISIONS:

In order to get maintain the organized storage and retrieval of data the platters are organized into specific structures. These specific structures include tracks, sectors, and clusters.

TRACKS:

Each platter is broken into thousands of tightly packed concentric circles, known as tracks. These tracks resemble the structure of annual rings of a tree. All the information stored on the hard disk is recorded in tracks. Starting from zero at the outer side of the platter, the number of tracks goes on increasing to the inner side. Each track can hold a large amount of data counting to thousands of bytes.

SECTORS:

Each track is further broken down into smaller units called sectors. As sector is the basic unit of data storage on a hard disk. A single track typically can have thousands of sectors and each sector can hold more than 512 bytes of data. A few additional bytes are required for control structures and error detection and correction.

CLUSTERS:

Sectors are often grouped together to form Clusters.

READ/WRITE HEADS:

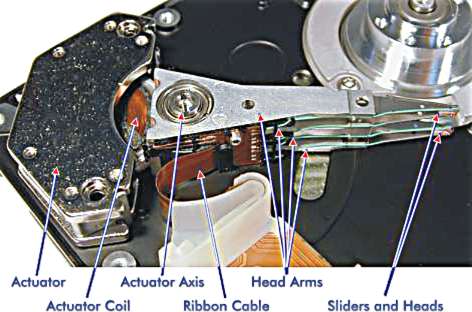

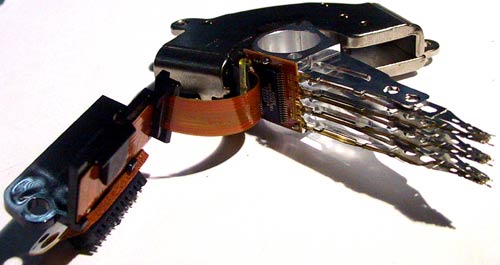

The heads are an interface between the magnetic media where the data is stored and electronic components in the hard disk. The heads convert the information, which is in the form of bits to magnetic pulses when it is to be stored on the platter and reverses the process while reading.

The heads are the most sophisticated part of the hard disk. Each platter has two read/write heads, one mounted on the top and the other one at the bottom. These heads are mounted on head sliders, which are suspended at the ends of head arms. The head arms are all fused into a singular structure called actuator, which is responsible for their movement.

THE SPINDLE MOTOR:

Spindle motor plays an important role in hard drive operation by turning the hard disk platters. A spindle motor must provide stable, reliable, and consistent turning power for many hours of continuous use. Many hard drive failures occur due to spindle motor not functioning properly

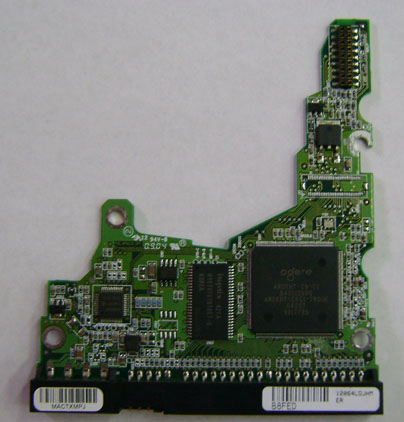

HARD DISK LOGIC BOARD:

Hard disk is made with an intelligent circuit board integrated into the hard disk unit. It is mounted on the bottom of the base casting exposed to the outer side. The read/write heads are linked to the logic board through a flexible ribbon cable.

DRIVE BAY:

The entire hard disk is mounted in an enclosure designed to protect it from the outside air. It is necessary to keep the internal environment of the hard disk free of dust and other contaminants. These contaminants may get accumulated in the gap between the read/write heads and the platters, which usually leads to head crashes.

The bottom of the disk is also called base casting. The drive mechanics are placed in the base casting and a cover, usually made up of aluminium is placed on top to enclose heads and platters. The entire contents placed on the base and cover chamber are collectively known as the head-disk assembly. Once this assembly is opened, it would instantly contaminate the contents and eventually ruin the drive.

On the bottom of the base casting is present the logic board, which is separated from the base casting using a cushioning material.